Capture high-resolution EL and UVF data in real-world environments to verify quality and risks for the full PV life cycle: from off-the-truck to end-of-life.

“

– Nate Matesich, Mechanical Engineer

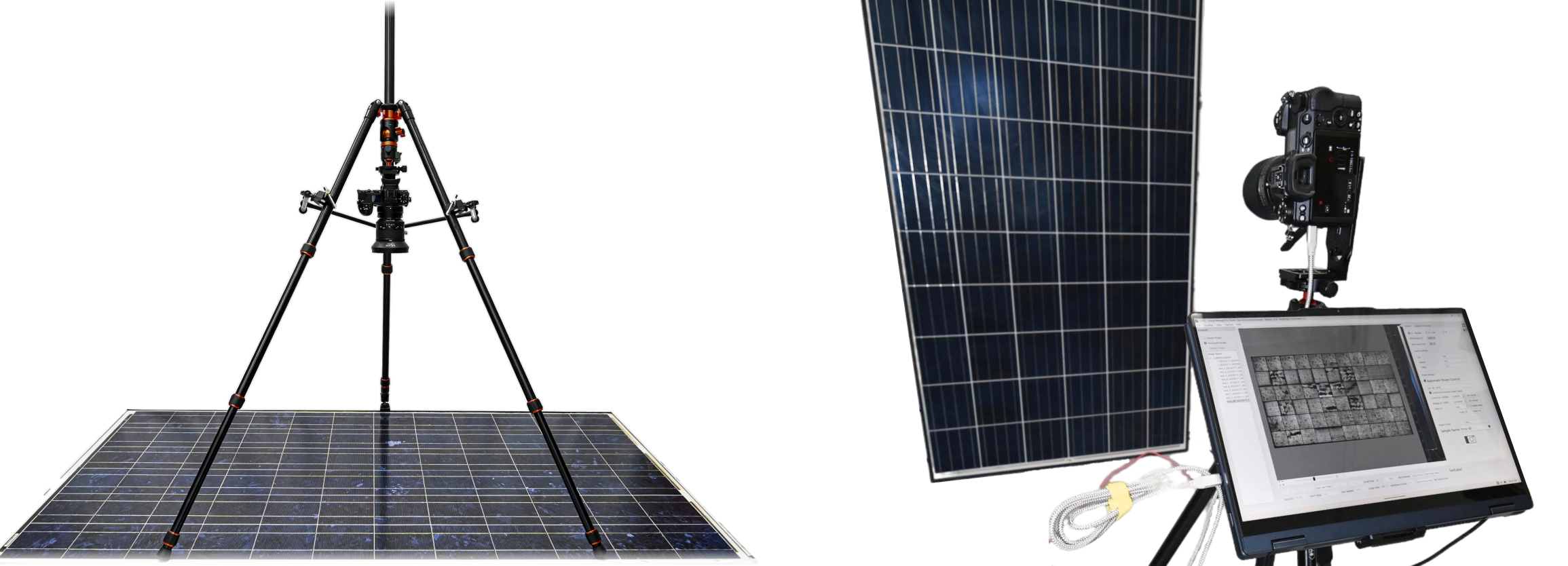

Field testing plays a critical role in verifying installation quality and diagnosing early-stage defects. BrightSpot’s portable EL and UVF tools bring advanced imaging to the field—bridging the gap between lab-grade diagnostics and on-site practicality.

➤ Detect defects in real-world conditions without dismantling the array.

➤ Reveal failure modes invisible to IR or IV testing.

➤ Validate module health before commissioning and track changes over time.

➤ Identify early signs of UV exposure and weathering effects.

➤ Ensure repeatability and comparability across sites and operators.

➤ Rapidly scan large sites without compromising image quality.

➤ Integrates into automated workflows for industrial-scale deployments.

Make sure you receive high quality panels made with a consistent Bill of Materials, installed without damage, and that maintain high energy delivery:

Prove the quality of your work, develop best practices, and differentiate your company based on quality

Prove to your customers that your equipment causes no damage, and use as feedback for product/process development

Reduce your risks by understanding panel quality – offer more competitive rates for low-risk systems and avoid high-risk projects

Differentiate your company with the highest quality and most informative tools

Maximize learning from your demonstration sites and use to troubleshoot customer issues

When panels leave the factory, they enter a world of variability— transport stress, handling, weather, and inconsistent installation quality. That’s why field-based inspection is essential. BrightSpot’s portable imaging systems deliver high-resolution EL and UVF images in the environments where performance truly matters: residential rooftops, commercial rooftops, and utility scale installations.

BrightSpot offers guidance, and consulting to help you get the most out of your EL/PL systems—whether you’re launching a new fab, scaling up field operations, or investigating complex failure modes.

Whether you’re selecting the right modules for a project or interpreting electroluminescence (EL) and ultraviolet fluorescence (UVF) data, our expert team helps reduce risk and improve decision-making at every stage of your solar project.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

UVF Kit is a tool every O&M technician should have, that enables you to quickly see cell cracks in fielded modules at night

UVF can reveal variations in encapsulant backsheet and metallization paste, which can affect degradation rates

EL and UVF can see solar cell cracks, even those which are not yet affecting power or visible in thermal IR images

UVF can reveal sealing problems at the junction box penetrations and the perimeter of the panel

EL can see Gridline Interruptions Caused by Soldering (GICS) – an industry-wide problem for modern, multi-wire panels

EL can reveal soldering problems between interconnect wires and the cell or the bussing wires – an industry-wide problem for modern, multi-wire panels

UVF can see cells that had been running hot due to cell cracking or partial shading

EL can see PID effects especially clearly with high/low current level testing

UVF can reveal sealing problems at the junction box penetrations and the perimeter of the panel

EL can see small shunts in thin-film panels, sometimes caused by partial shade induced damage

EL and UVF can see metallization corrosion problems that increase series resistance losses

Control

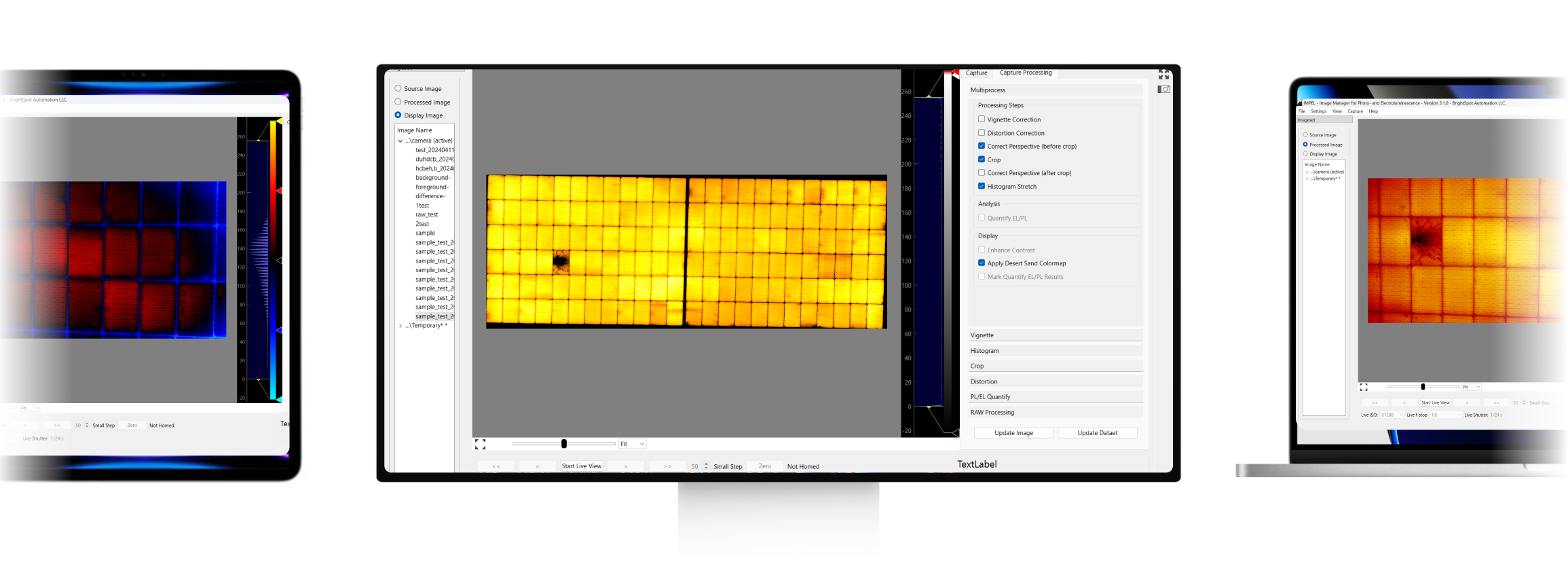

IMPEL is the unified control platform for BrightSpot imaging systems, enabling seamless coordination of camera, light sources, and power supply. From a single interface, users can adjust exposure settings, trigger PL or EL sequences, and automate capture workflows across multiple system components.

Enhancement

Built-in image processing tools help users sharpen contrast, highlight defects, and visualize subtle variations in cell or panel performance. With support for custom filters and multispectral imaging, IMPEL ensures every captured frame delivers actionable insights, whether in R&D or field diagnostics.

Report

IMPEL simplifies documentation by generating detailed reports with embedded images, metadata, and measurement context. Export results for internal QA, client acceptance, or long-term traceability – standardized and ready to share.

We bring advanced imaging out of the lab and into the real world—without compromising on clarity or diagnostic power. BrightSpot’s field inspection systems are engineered to perform in dynamic, uncontrolled environments while delivering reliable, repeatable insights.

Reveal microcracks, shunts, junction defects, and degradation across cells and modules. PL is especially valuable for non-contact inspection and layer-specific insights in multi-junction or tandem architectures.

UVF imaging highlights encapsulant degradation, PID (potential-induced degradation), corrosion, and backsheet contamination. It’s a powerful diagnostic tool, especially in aging or damaged modules.

The latest publications and technical outputs from BrightSpot Automation

+1 401.536.8396

sales@brightspotautomation.com

BrightSpot Automation LLC Boulder, CO 80301 USA

ⓒ2025 BrightSpot Automation